Air Abrasion Repairs

Kreativ Mach 4,5,5+,6,7 & 8

Repairs and Tune-ups available for these machines:

- Ticking leaks

- Compressor

- Pinch valves

- Electronics

Most parts in stock:

- Pinch valves

- Tubing and Mac valve replacements

- Handpiece upgrade replacements

- Powder

- Filters

Handpiece and nozzle replacement kits

Includes:

Stainless steel articulating handpiece with five assorted tips. (your choice in colors)

Part #95-5923

Handpiece and nozzle replacement kits

Includes:

Stainless steel articulating handpiece with ten assorted tips and hose adapter. (Your choice in colors) P/N 95-5923-1

Call for complete overhauls!

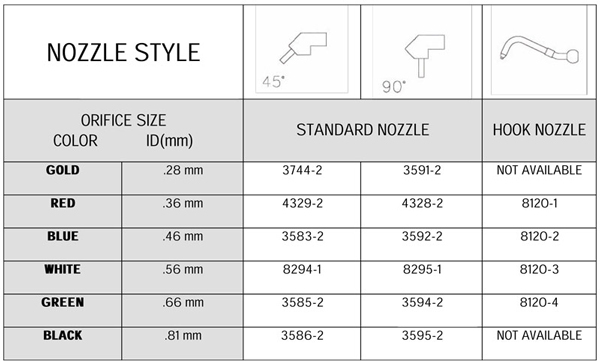

Replacement Nozzle Kit Chart:

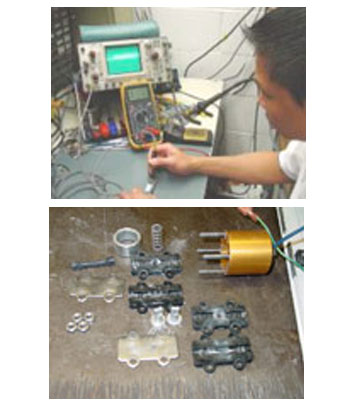

MidWest Air Abrasion Repair

Complete tune-ups available

Services for tower or counter top systems

- Complete Overhauls: Contact us for quotation on your machine

- Tune-ups and clean-outs

- Handpiece replacement kits

- Trouble shooting via phone: $50.00 one time fee (first 5 min. n/c)

- Replacement parts, have most requested parts in stock

- Pinch valve tubes

- Handpiece hose with fittings

- Handpiece replacements

- Internal plumbing fittings and hoses

- Breather vents

Routine Maintenance Kits Available:

MidWest Air Touch Preventative Maintenance Kit

- Part#95-5827-1 Contains the following service parts:

- Two pinch tubes for dual canisters

- Two O-rings for dual cap Lids

- One each, small & large O-ring for handpiece connector

One air intake filter element for tower compressor systems

- Abrasive material: 27µ grit and 50µ grit aluminum oxide powderair

- Any questions please contact us, we can help you!

Air Technique / AirDent 2

American Medical Technologies KCP 1000 WhisperJet

The Quick Fixes That May Save Time and Money

Powder Clog:

- Handpiece – Remove handpiece, run wire or endo file through opening in the nozzle. If handpiece is wet, it must be allowed to dry completely

- Powder Chamber – Evacuate all powder from chamber (leave chamber empty.) Replace powder caps and turn the unit on. Set the parameters to 120psi (or highest available), Continuous, Boost, Select appropriate powder size, and Ready. Blow air through the chamber for 40-60 seconds. Refill powder and continue

- Check Lids– Remove o-rings from the powder caps. Clean the o-rings and the inside of the powder caps

- Software Glitch – Turn unit off, wait 15 seconds, then turn unit on again

- Check Air Supply (CO2) – When any error message is received on a CO2 unit, always check the regulator to ensure that there is more than 500 psi in the cylinder

- Slow Vent – Remove the vent muffler

Installation Tips:

- Purge air through the unit prior to adding powder

- Warn staff of connecting unit to water lines instead of air